THE TECHNIQUE OF CREATING MOKUME GANE

Mokume Gane (Japanese for 'woodgrain in metal') is a technique of fusing and forging precious metals. It was developed in 17th Century Japan and used to create Samurai swords.

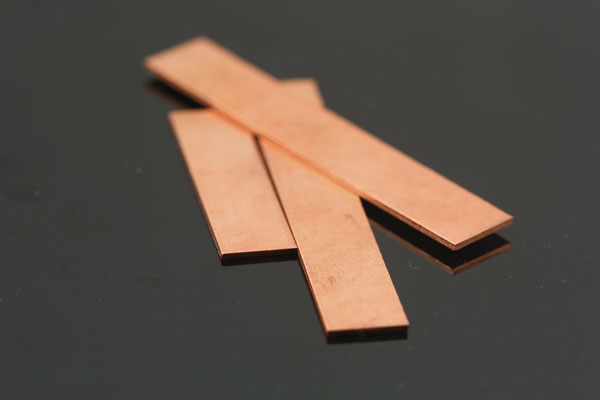

This long, complicated process begins when Eytan makes flat plates of various metals using different alloys. For example, 18 karat white, yellow or rose gold, sterling silver, Palladium, 22 karat gold in all colours and also Shakudo - which is made of 96% copper mixed with 4% pure gold. Each of these alloys has a prominent colour, creating the contrast between them in the final piece.

The "pile" of different metals - containing from 12 to many more layers (the more - the merrier) is then put into the kiln, stacked tightly to help it fuse perfectly. The fusion is done only by heat and great pressure - not by the conventional joining method of soldering.

Eytan then takes the billet out of the kiln. The great challenge of this process is to get the perfect fusion result without any of the metals collapsing and melting - and believe me, mistakes do happen and they are very costly.

After hours of cooling, he begins to forge and pattern the metal in various ways to create the intricate patterns in the metal, exposing all the different layers and colours.

It is only then that Eytan actually makes the piece, using the forged billet. The finished piece is definitely worth this difficult and time-consuming process. The results are unique, one off creations with a beautifully organic look and feel to them.